Published date:

Electric Solution for Panini Branding Machine

Roberts Bakery in Ilkeston, Derbyshire contacted Heatrod to look for an electric solution for their panini branding machine, as their existing gas fired system had become inconsistent and was going to be costly to refurbish.

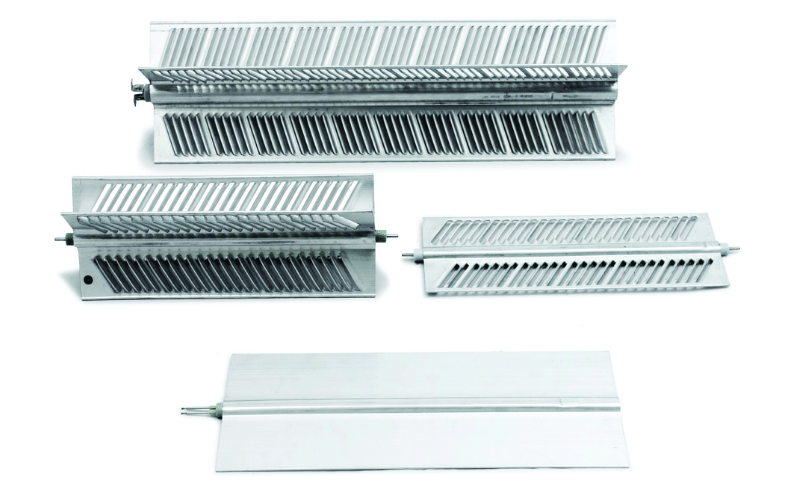

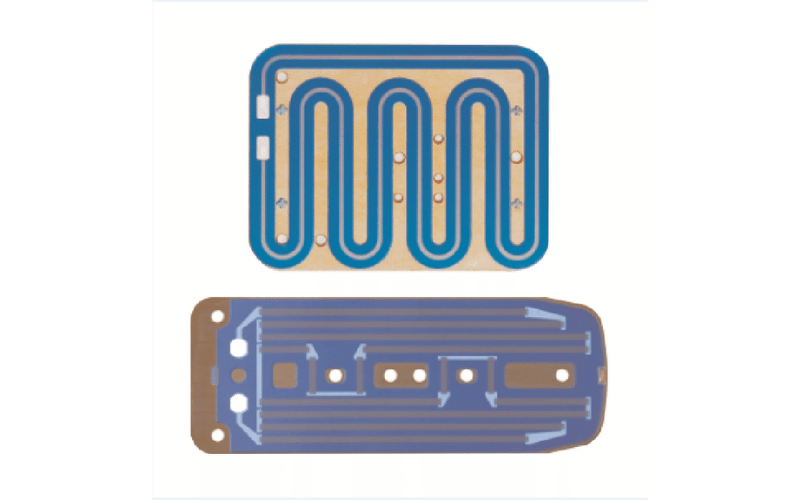

Their existing gas system heated up a large heavy top plate

with ribs on the surface, used to apply the scorched finish on

the top of the panini. This had become inconsistent and they

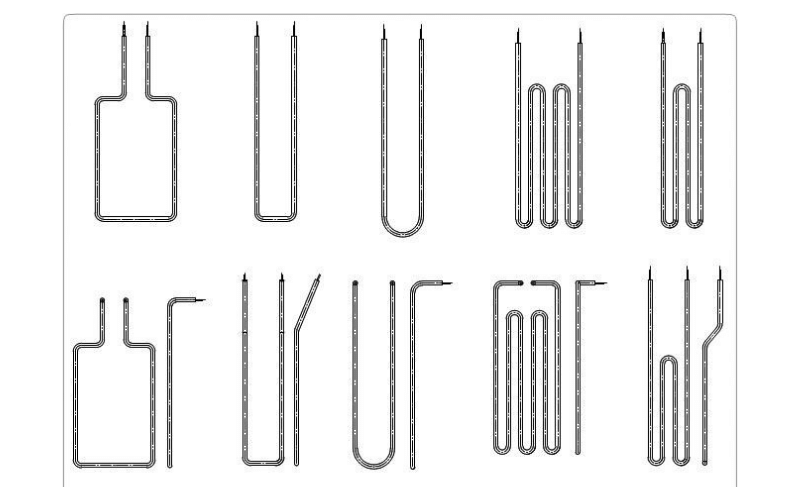

had several rejects because of this. Heatrod initially

provided a handheld unit with formed elements for testing,

proving successful. Following this we designed a solution

which consisted of 33 formed elements which then fitted

into a custom frame. The paninis are fed into the machine

manually and are indexed under the heaters, where the plate

is lowered onto the panini for less than half a second, before

the finished goods appear at the other side.

Technical details:

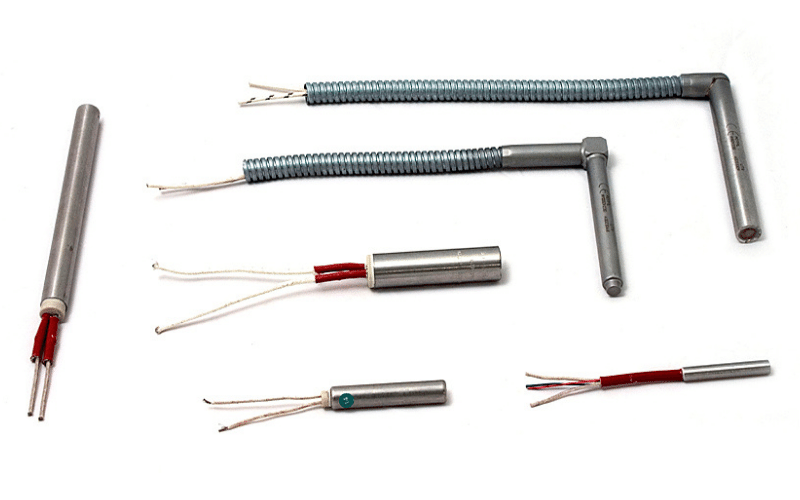

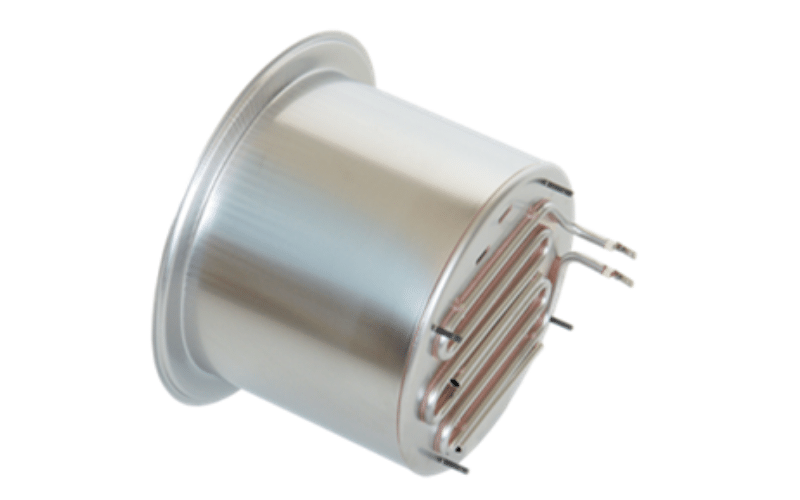

Custom formed Incoloy 800 element, 240v, 800watt.

Formed to a multi zig-zag design to suit required finish on product.

Threaded fittings attached at either end so the elements can be easily fitted into a custom frame.

Temperature is controlled by closed loop PID Control.

Says Robert Bates, Senior Engineer at Roberts Bakery:

Everyone is super happy with the performance of the machine and resulting appearance of the product, the definition of the brand lines is better than anything we’ve seen for a number of years. Even with brand new plates the gas system was never as good as what we have now.

Heatrod offer design, production and supply of electric heating for the process industry, providing products meeting all relevant standards and tests. Certifying products to customer specifications, we design, develop and manufacture all types of systems for electrical heating of gases, liquids, vapours and solids.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)