BRAUDE Corrosion Resistant Heaters

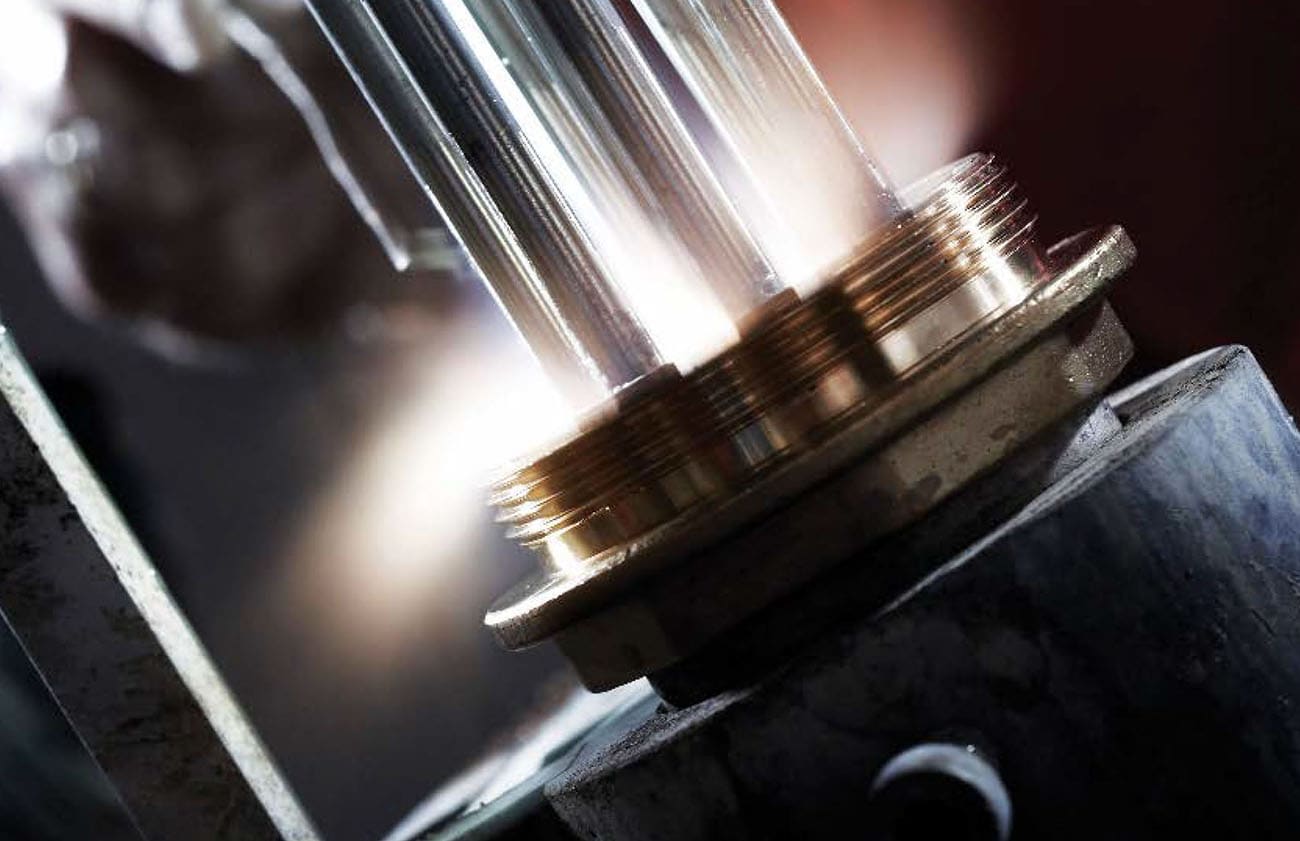

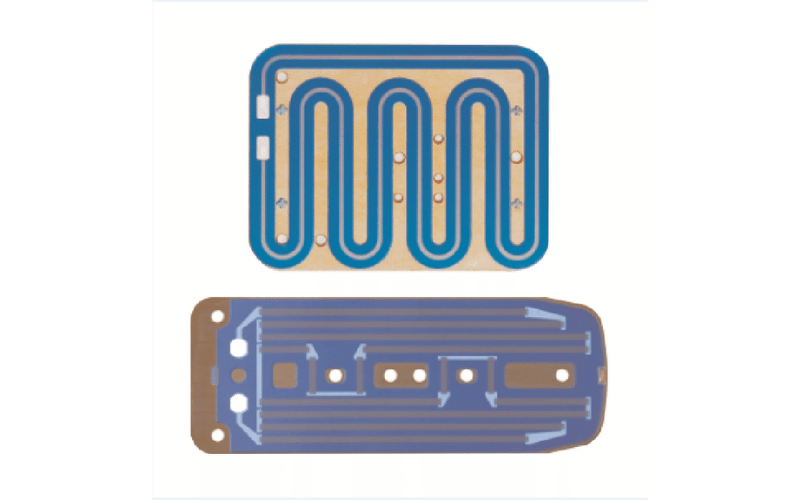

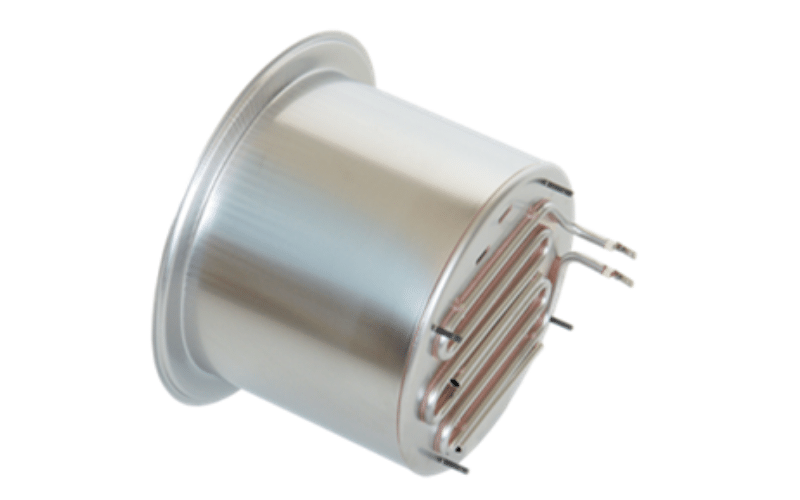

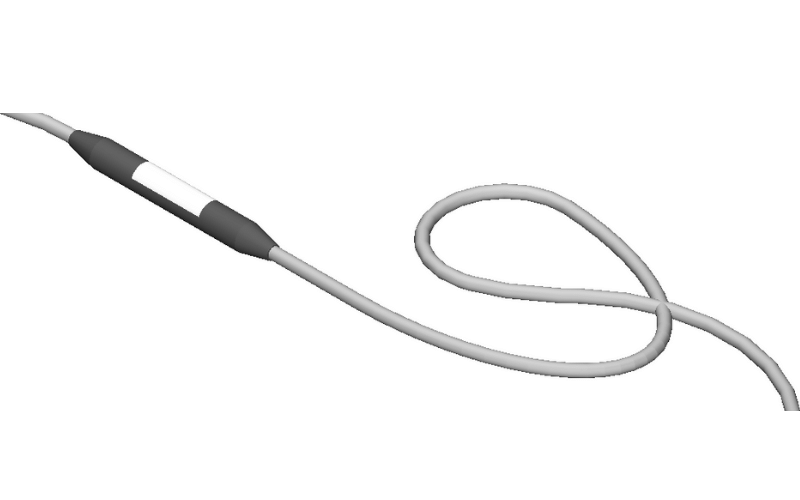

The Polaris Modular fluoropolymer immersion heaters are designed for use where aggressive chemicals need to be heated to temperatures up to 100°C, and have optimum chemical resistance against corrosion caused by chemicals such as nitric, hydrochloric, sulphuric and hydrofluoric acids, and are inert enough to be used where non-contamination is a requirement.

They are small enough to fit behind anode baskets and in other confined operating areas; the Polaris Modular will cope with all the special requirements experienced by the metal finishing and allied industries.

Example of Applications

- Electroplating

- Electroless Plating

- Chemical Polishing

- Hard and soft Anodising

- Frost protection for chemical tanks

- Marine water

- Acid Pickling and Etching

- Chemical Milling

Benefits

- Designed for process applications

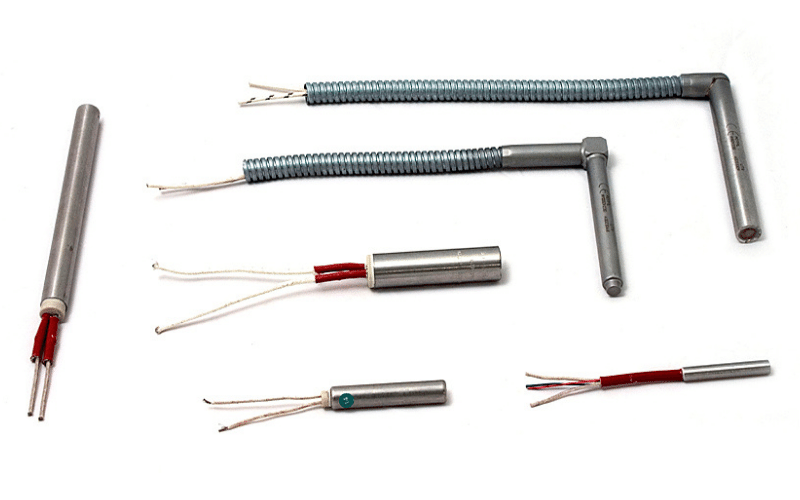

- Sizes up to 18kW, 3 phase

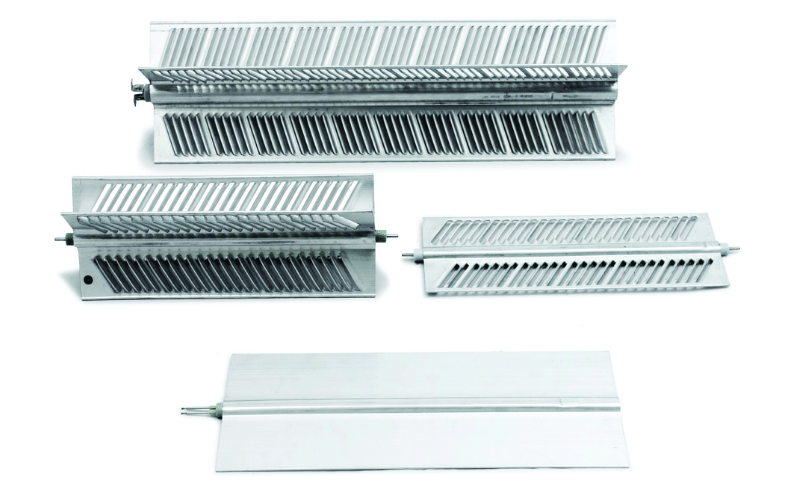

- Heaters for all process tanks

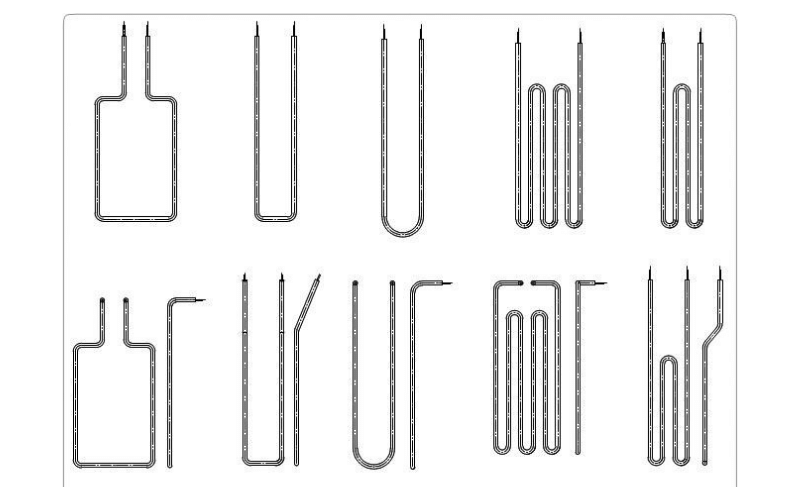

- Wide variety of styles to choose from

- Full range of chemically resistant heaters

- Compatible with Braudemaster controllers

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)