Industrial Flow Heaters

Backer Process Heating (part of our parent company) designs, develops and manufactures all types of systems for electrical heating of gases, liquids, vapours and solids.

We work closely together with our customers to manufacture systems meeting the most stringent international standards. Our expertise in the field of electrical heating covers the chemical, pharmaceutical, petrol chemical (both onshore and offshore applications), steel, textile, glass, power generation and foodstuff industries. In fact, any application requiring process heating.

We supply heating elements, pressure vessels, and control panels/systems, all fully tested and certified to meet the required standards, including Ex-proof.

Example of Applications

- Chemical process

- Pharmaceutical manufacturing

- Petrochem and oil industry

- Steel manufacturing

- Textile manufacturing

- Glass industry

- Power generation

- Food processing

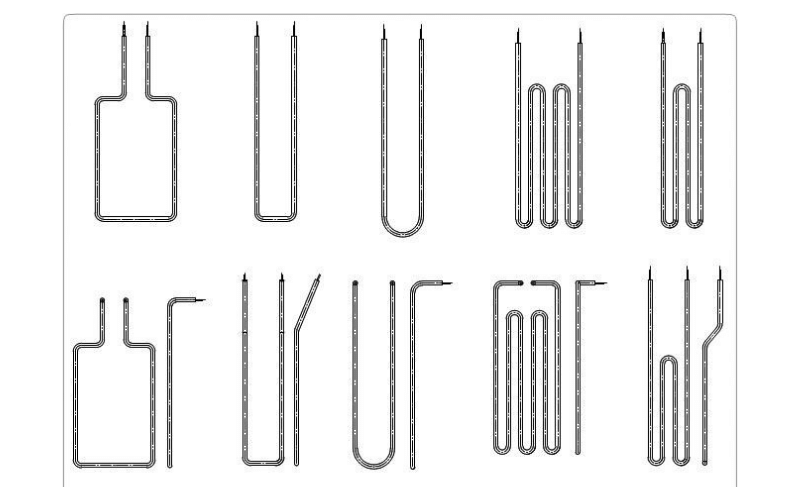

Products

- Flow modules for the heating of oil, water and other fluids

- External flow modules for the heating of oil, water and other fluids

- Glycol heaters

- Flow modules for the heating of air and liquids

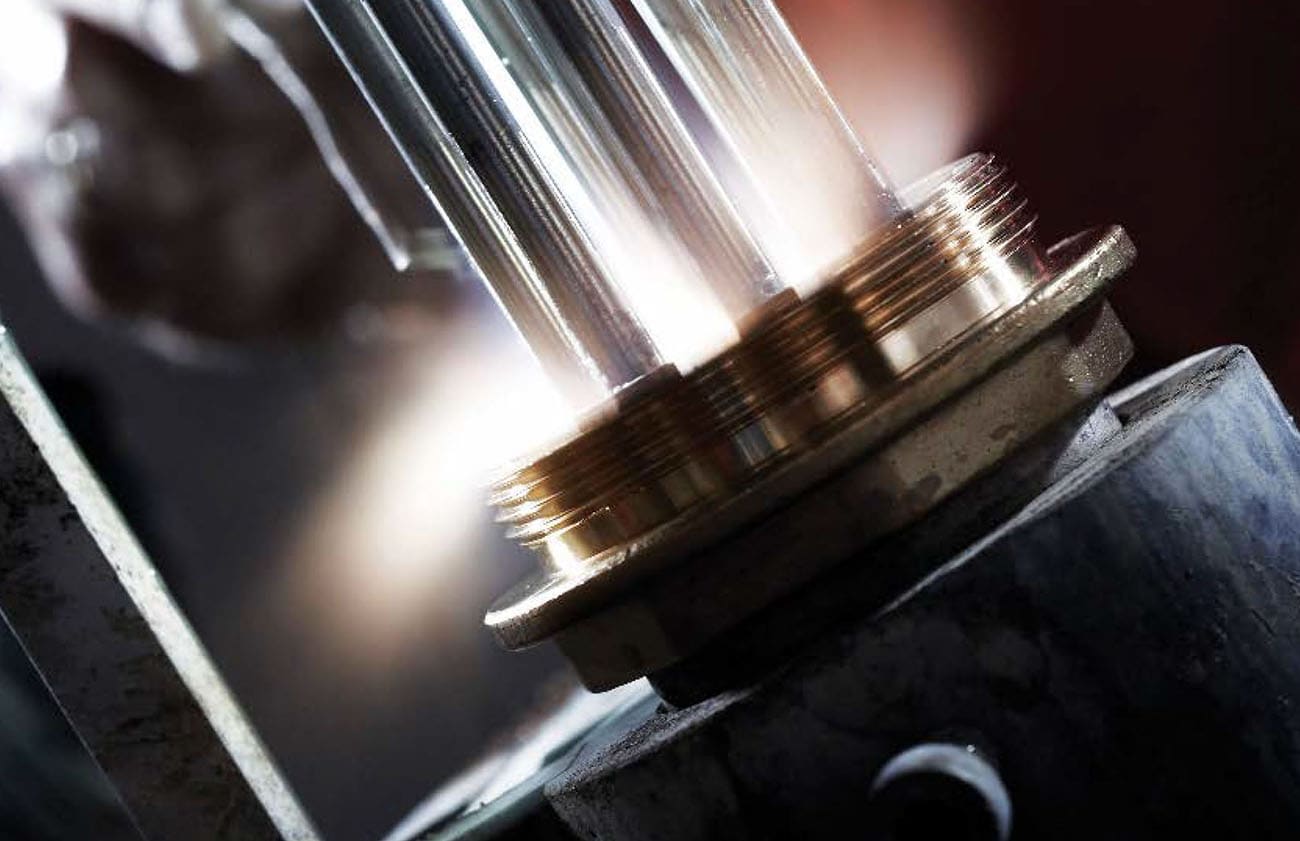

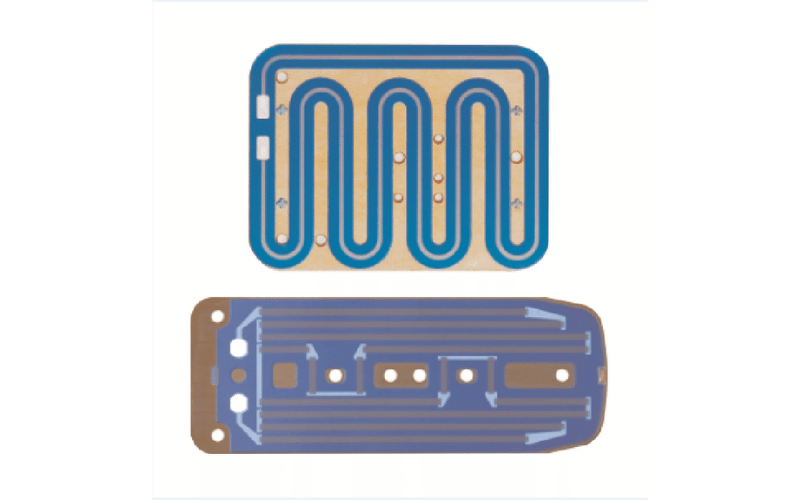

Flow modules for the heating of Oil, Water and other Fluids

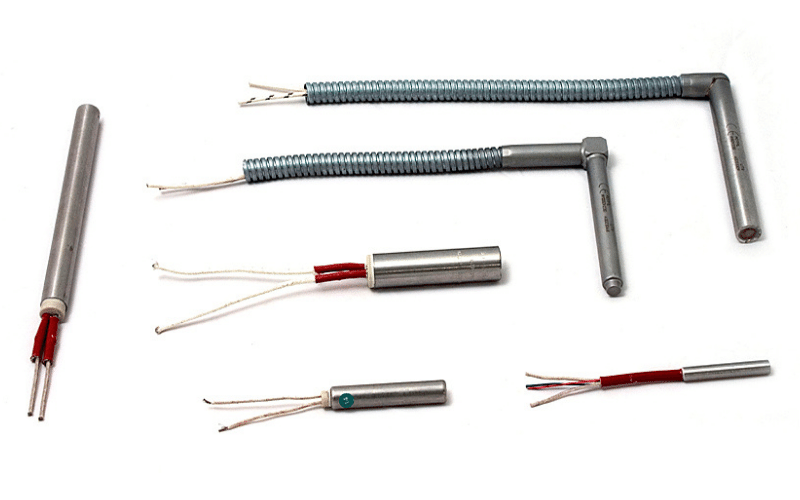

Manufactured using our vat heating elements which can then be fitted into a suitable container for recirculating the fluid.

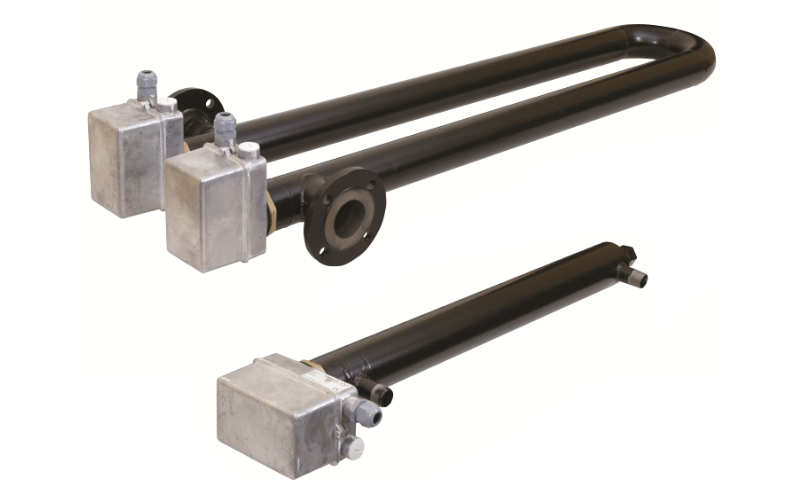

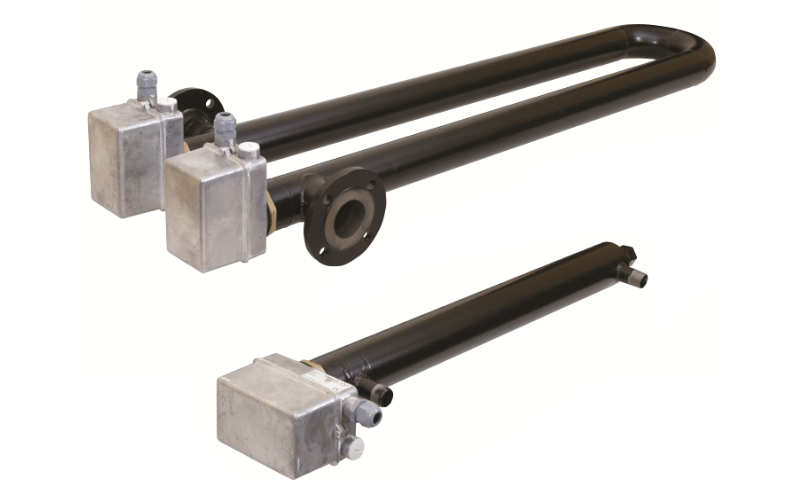

External Flow modules for the heating of Oil, Water and other Fluid

With motor, pump and expansion valve. For heating of lubricating oil in gearboxes, e.g. in Arctic areas where additional heating is required. The built-in pump circulates the lubrication oil through the gearbox. The flow heater is equipped with a pump, temperature limiter, and PT100 sensor. ETL approved.

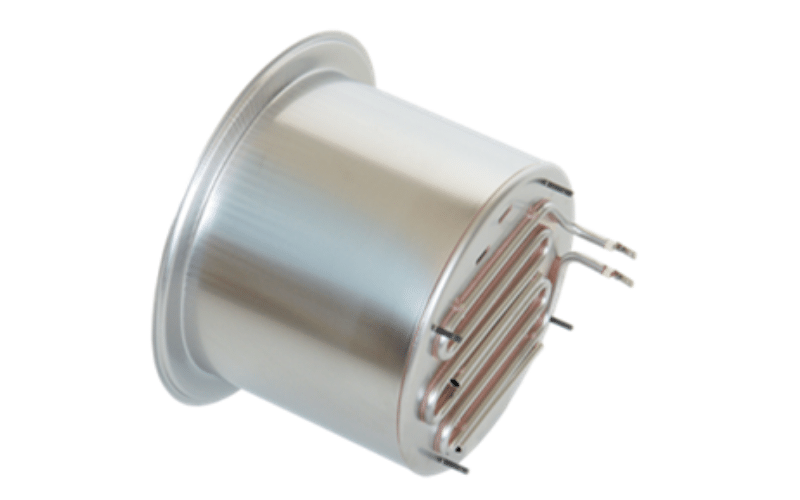

Glycol heaters

Our glycol heaters are used for pre-heating of cooling water in the cooling/heating system in converters in wind turbines before start-up of the wind turbine. The glycol heaters are delivered in various materials and

designs to meet customer requirement.

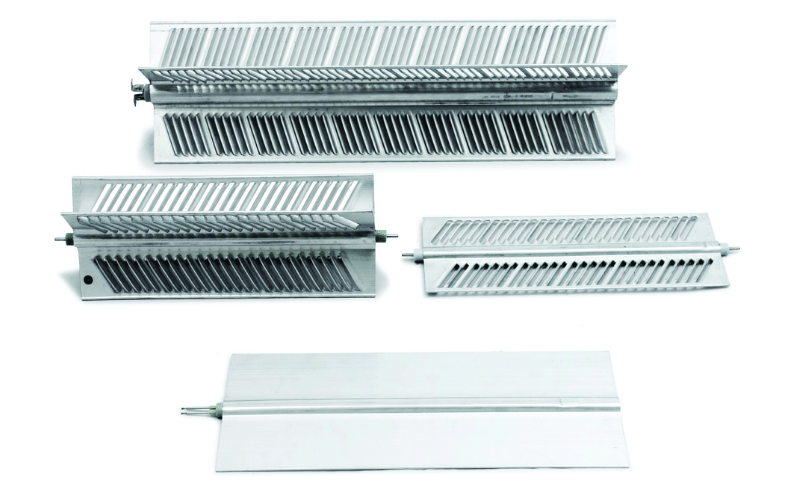

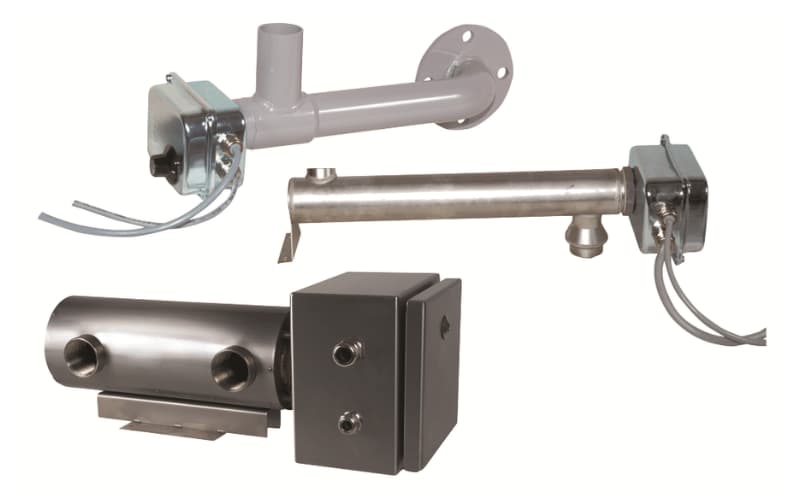

Flow Modules for the Heating of Air and Liquids

Manufactured in materials and dimensions according to customer requirements. Can be built-up easily and mounted as required. Pressure, temperature levels and materials used will depend on the specific project

and application. After installation, the equipment is

pressure tested according to specification.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)