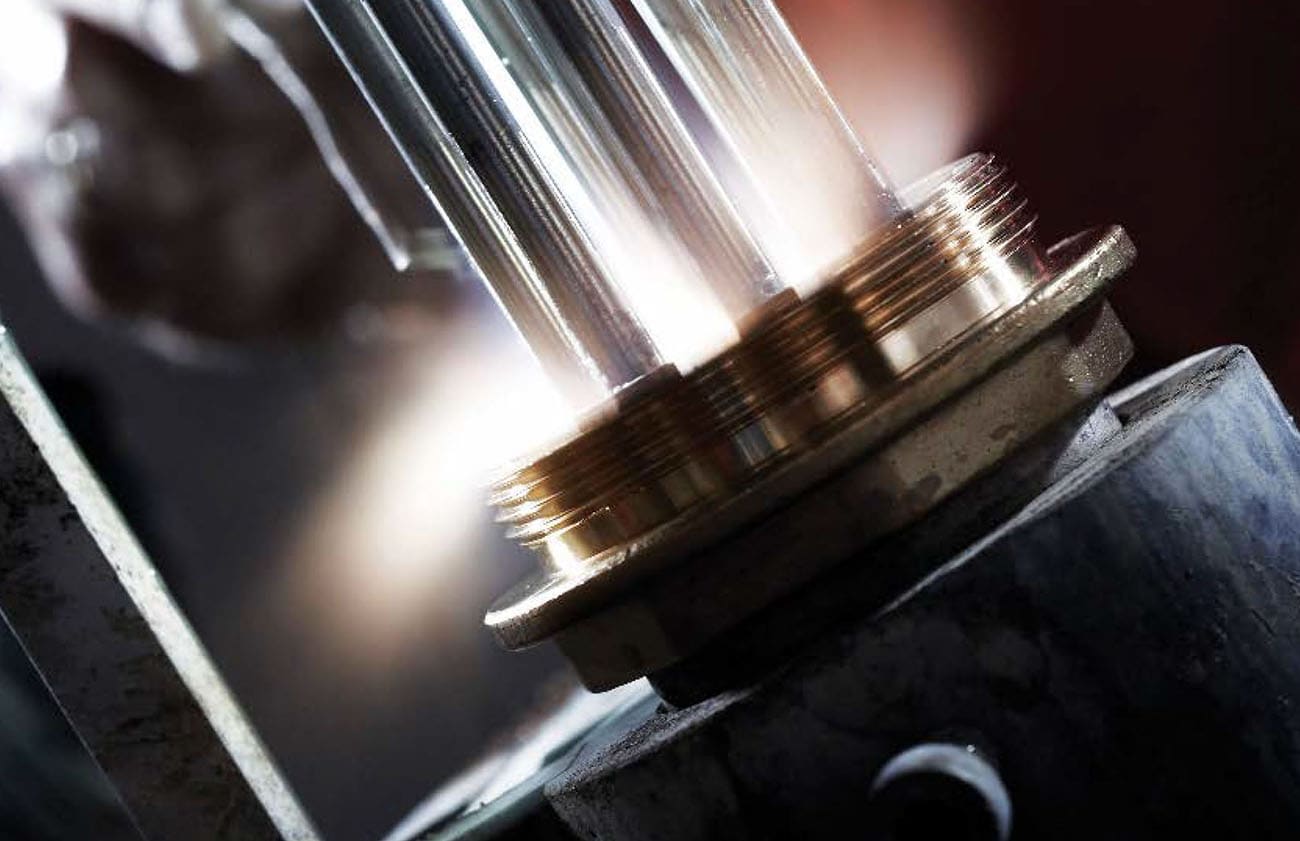

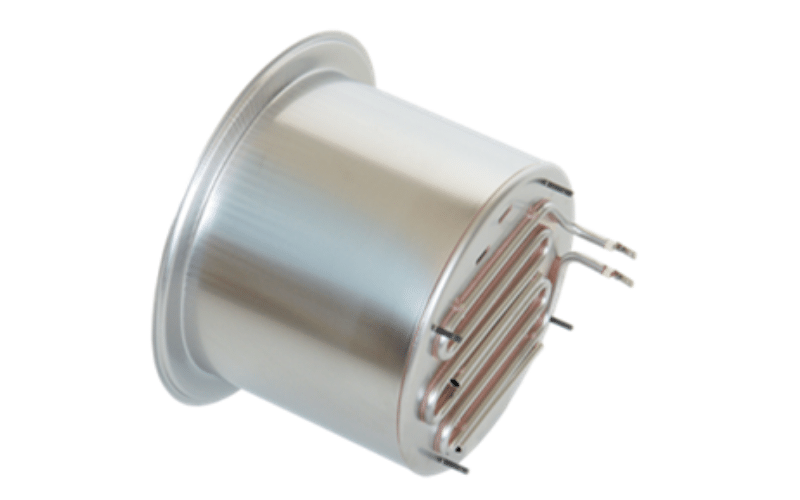

Thick Film Elements

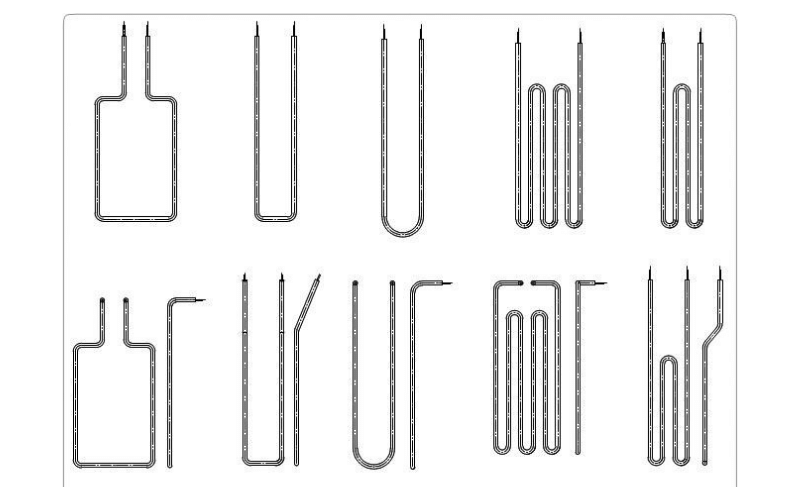

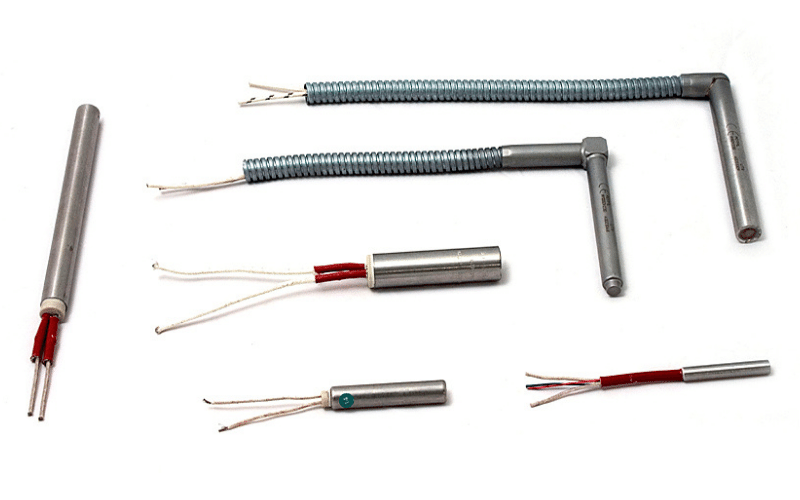

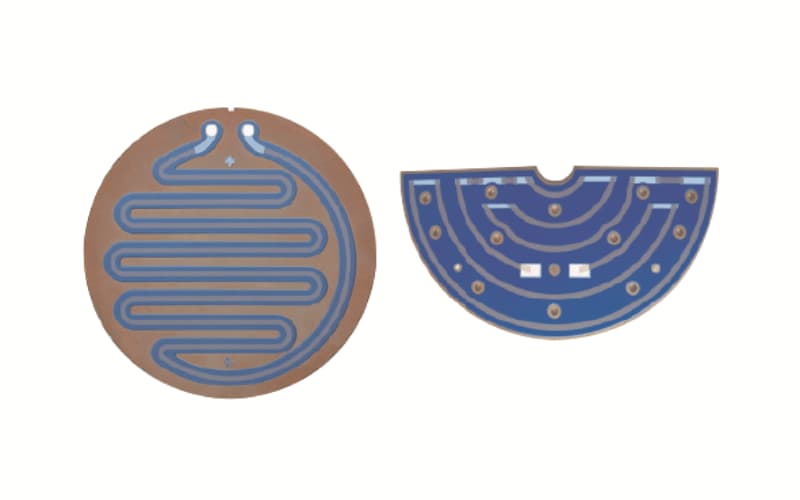

We manufacture thick film elements which give quick heating and have good heat transmission ability. The elements are easy to adapt to different shapes and patterns and and can be bespoke manufactured for higher volume applications.

These heating elements are intended for contact heating of flat surfaces and for heating of liquids through a flat wall. Compared with an ordinary tubular heating element, a heating element on a sheet metal provides substantially better heat transfer into a flat wall. These elements can also be of benefit in applications where low thickness of the heating element is important.

If you are considering the application of thick film elements, a consultation with our Technical Department is highly recommended for detailed specification of particular requirements.

Example of Applications

- Water/beverage dispensers

- Swimming pools

- Tubular flow through heaters

- Irons

- Water boilers

- Washing machines

- Applicators for ski wax

Benefits

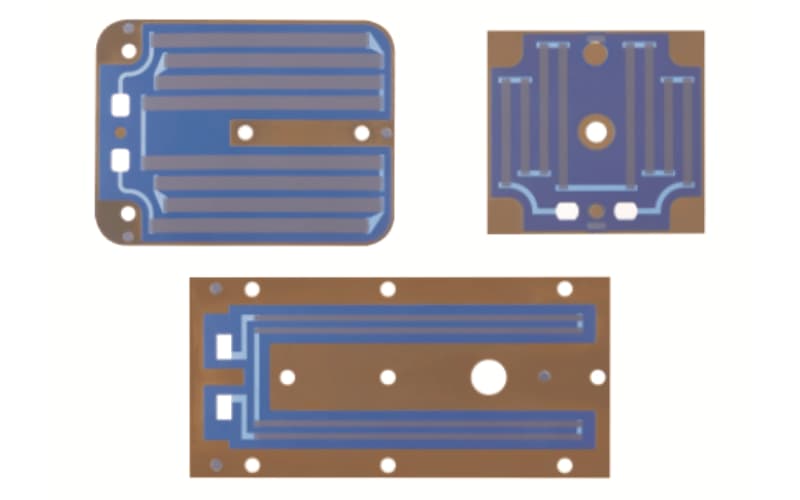

- Large heating surfaces

- Compact design

- Fast heating

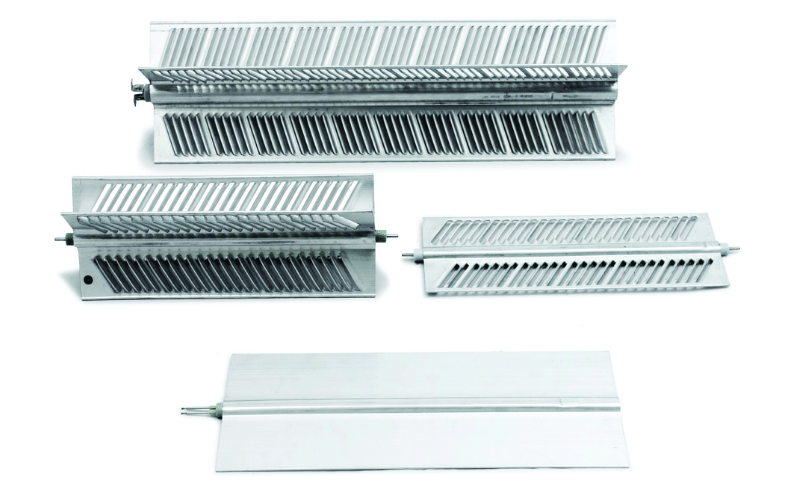

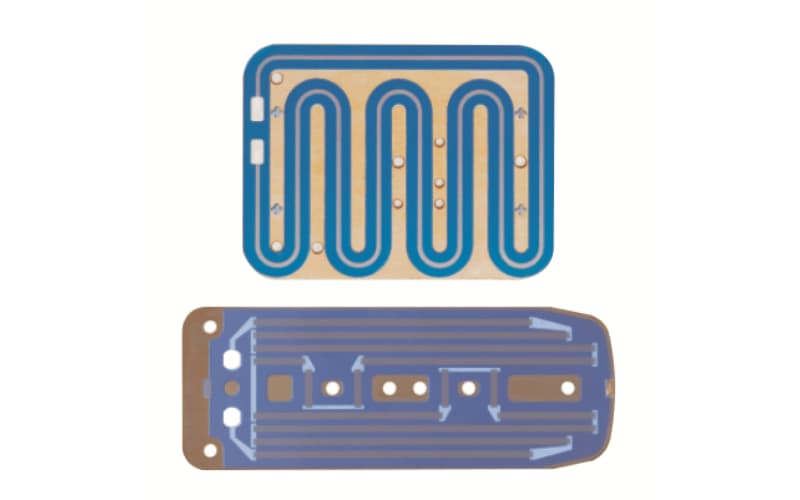

- Various through-flow heaters for industrial applications

Suitable for applications where extra fast heating of flowing liquid is required. Ideal heat transfer is guaranteed by flowing of liquid through all inner surface of the heating element. The small dimensions of the element enables usage and placement in applications with limited space.

Product Specification:

- High performance - power densities up to 50W/cm²

- High operating temperature - up to 350°C

- For direct liquid heating or contact heating of flat surfaces

- Electrical strength up to several kW

- Mechanically stable, self supporting steel substrate

- Simple application of holes, screws, nuts, welds, any flat shape

- Does not absorb humidity

- Temperature profile according to requirements

-

Technical data

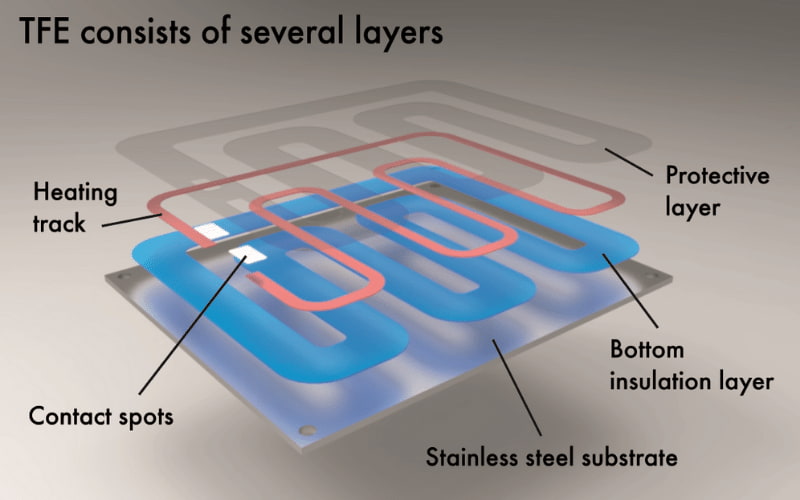

Thick film heating elements are manufactured in a completely different way than ordinary tubular heating elements. A thick film heating element consists of a stainless steel or ceramic substrate (plate), on which an insulation layer (meets the requirements for dielectrical strength) is printed, then a layer of resistive paste, followed by a contact and connective layer, and finally all these layers are covered with top enamel layer (providing protection against mechanical damage). The individual layers are applied by screen printing and each layer is dried and fired afterwards. Maximum protection from dirt and dust is essential through the whole production process. Production runs in air-conditioned areas meeting the requirements for rooms with high air purity class.

Thus precisely manufactured thick film heating elements feature a quick temperature rise, an extremely low thermal capacity and minimum temperature fluctuations. Their high efficiency of 70 – 95% depends on the mode of operation (direct or indirect heating).

Material

Thick film on plane plate of stainless steel, AISI 304/EN1.4301

Dimension

Max length, width, height 150mm

Assembly

Fixing to the objct

Connections

Flat connectors, cable

Additional

Operating temperature max 500°C

Substrates made of stainless steel according to standards AISI 430, DIN 1.4016 are used. Tests with stainless steel AISI 304, DIN 1.4301 were carried out as well. The substrate (printing area) must be flat, but can be of various shapes and can contain openings manufactured in advance (before the printing process).

The elements operate at standard line voltage (up to 400 V). Thick film heating elements feature very high surface power density(up to tens W/cm2). Nevertheless, their operation conditions should be adjusted according to the particular application – adequate heat transfer should be provided so that the surface temperature does not exceed 300 °C.

Thick film heating elements feature a significant PTC effect (its resistance rises with rising temperature, so its power decreases consecutively). Thus, resistance at room temperature and nominal voltage are specified as technical parameters for thick film heating elements.

Other cables and fixings are available - please enquire.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)